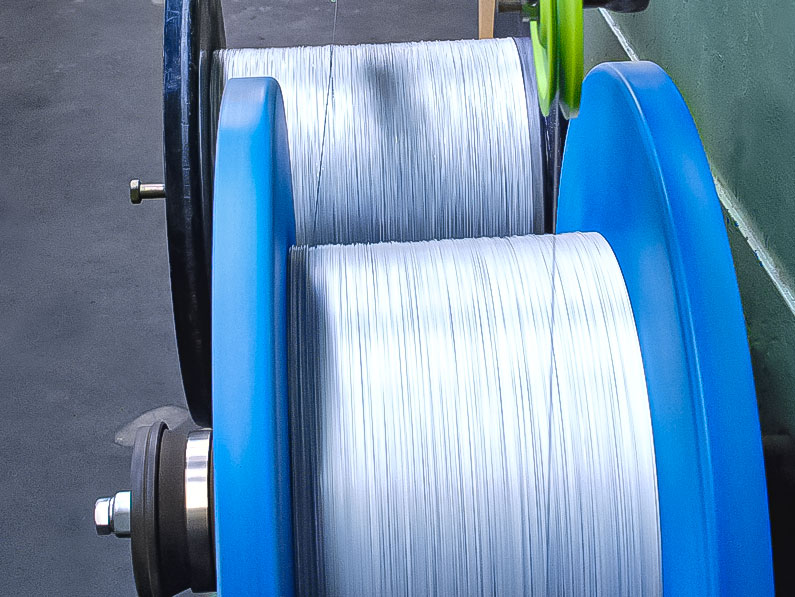

Tin Electroplating on Round Wire

Tin Electroplating of wire at Summit Plating is an economical solution for improving connective usability and durability.

Tin Electroplating characteristics

Tin electroplating enhancements include increased operating temperature range and improved solder-ability. Tin plating on certain wires, (especially Copper) does have a limited solder-ability shelf-life due to an inter-metallic interaction that naturally occurs over time between the base wire and the tin coating. If considering this option, it should be noted that proper packaging can significantly extend the shelf life of Tin Plated Wire.

Contact Summit Plating

Learn how Summit Plating can improve your bottom line — contact us by phone or email to request a no hassle QUOTE today! We look forward to assisting you.

“We appreciate your trust, respect your time, and look forward to helping you discover a better electroplating solution for your next project!”

Leeza Day —

Management, Summit

(860) 283-4391

fax (860) 283-4010

1430 Waterbury Road

Thomaston, CT 06787