Metal Plating for Oil and Gas Industries

Summit Plating’s metal plating expertise aids Oil and Gas companies in their quest to harness our nation’s energy.

Oil and gas mining environments are harsh, and the aggressive, stressful nature of the activity tests the durability of the extracting machinery and equipment used. Because the durability of tools used to gain natural resources is mission critical, Metal plating and finishing is an important characteristic that manufacturers of gas and equipment rely on to ensure optimum function, protect against corrosion, and increase tool lifespan.

Summit Plating Electroplating and Electroless Plating for Gas & Oil.

In general, Summit Plating harnesses the strengths of Electroplating for parts used in the extraction and collection of oil and gas. Plating with a variety of precious, semi-precious, and common metals like gold, silver, and nickel delivers important performance characteristics:

Performance advantages include:

- Resistance to friction wear

- Resistance to oxidation and corrosion

- Increased electrical conductivity

- Increased resistance to heat

- Strengthened part integrity through increased hardness

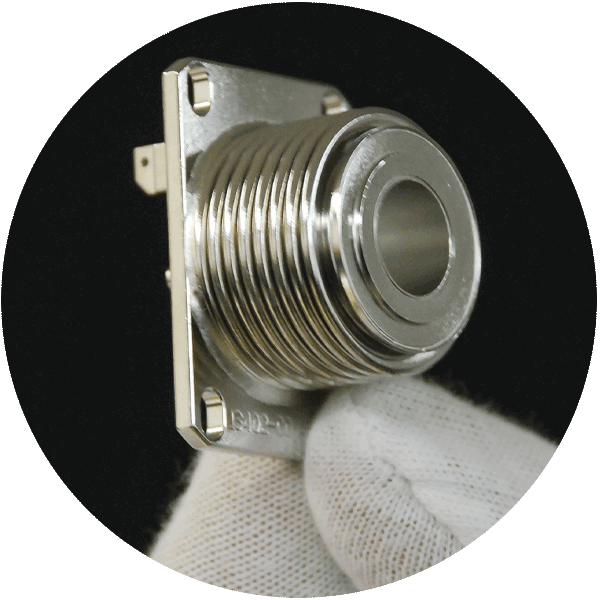

Typical components we can and have plated for use in the gas and oil industries include:

- Electronic relays and switches

- Hydraulics control components

- Mining measurement apparatus and gauges

- Mining equipment fasteners, connectors and brackets

- Electrical wire used in aerospace systems

Electroplating Certifications | Industries:

Contact Summit Plating

Learn how Summit Plating can improve your bottom line — contact us by phone or email to request a no hassle QUOTE today! We look forward to assisting you.

“We appreciate your trust, respect your time, and look forward to helping you discover a better electroplating solution for your next project!”

Leeza Day —

Management, Summit

(860) 283-4391

fax (860) 283-4010

1430 Waterbury Road

Thomaston, CT 06787