Electroplating Continuous Stamped Parts and Metal Stock

Electroplating Continuous Stamped Parts and Coiled Metal Stock – quickly and efficiently

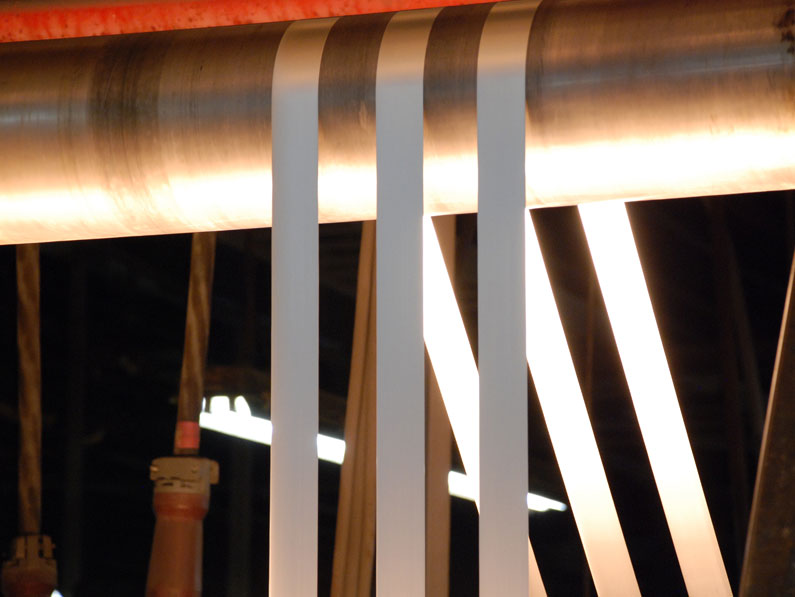

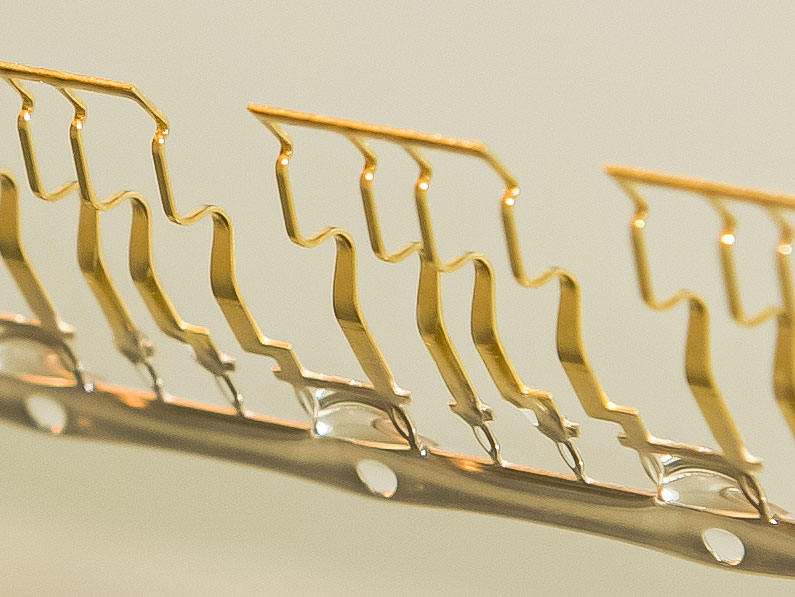

Summit’s Electroplating perfects the process of coating coiled metal stock and continuous fabricated stampings. Using proven and proprietary plating techniques, strips of material are electroplated as they are run “continuously” through a turnkey plating assembly that includes cleaning, chemical preparation, electrical anode exposure, plating material bath immersion and specialty surface finishing.

Along with speed efficiencies, the continuous, smooth, controlled movement of the material through strategically arranged plating anodes delivers very uniform electroplating with excellent edge-to-edge and side-to-side plating thickness uniformity. These important charasteristics are monitored and validated through out strict, ongoing QA protocol.

Enhanced appearance, strengthened corrosion and abrasion resistance, improved conductivity, and “economies of scale” are the main strengths achieved through Summit Continuous Part electroplating.

Contact Summit Plating

Learn how Summit Plating can improve your bottom line — contact us by phone or email to request a no hassle QUOTE today! We look forward to assisting you.

“We appreciate your trust, respect your time, and look forward to helping you discover a better electroplating solution for your next project!”

Leeza Day —

Management, Summit

(860) 283-4391

fax (860) 283-4010

1430 Waterbury Road

Thomaston, CT 06787